The Shocking Simpcityforum Truth Experts Are Trying To Bury By Pyramid Productions On Apple Podcasts

Today the controller has to be power cycled in order to reset the tick. By default, the log will be saved in the desktop location of the administrator user under which you are running the command. In a parallel thread, you can define the conveyor actual position and motion by updating the tick.

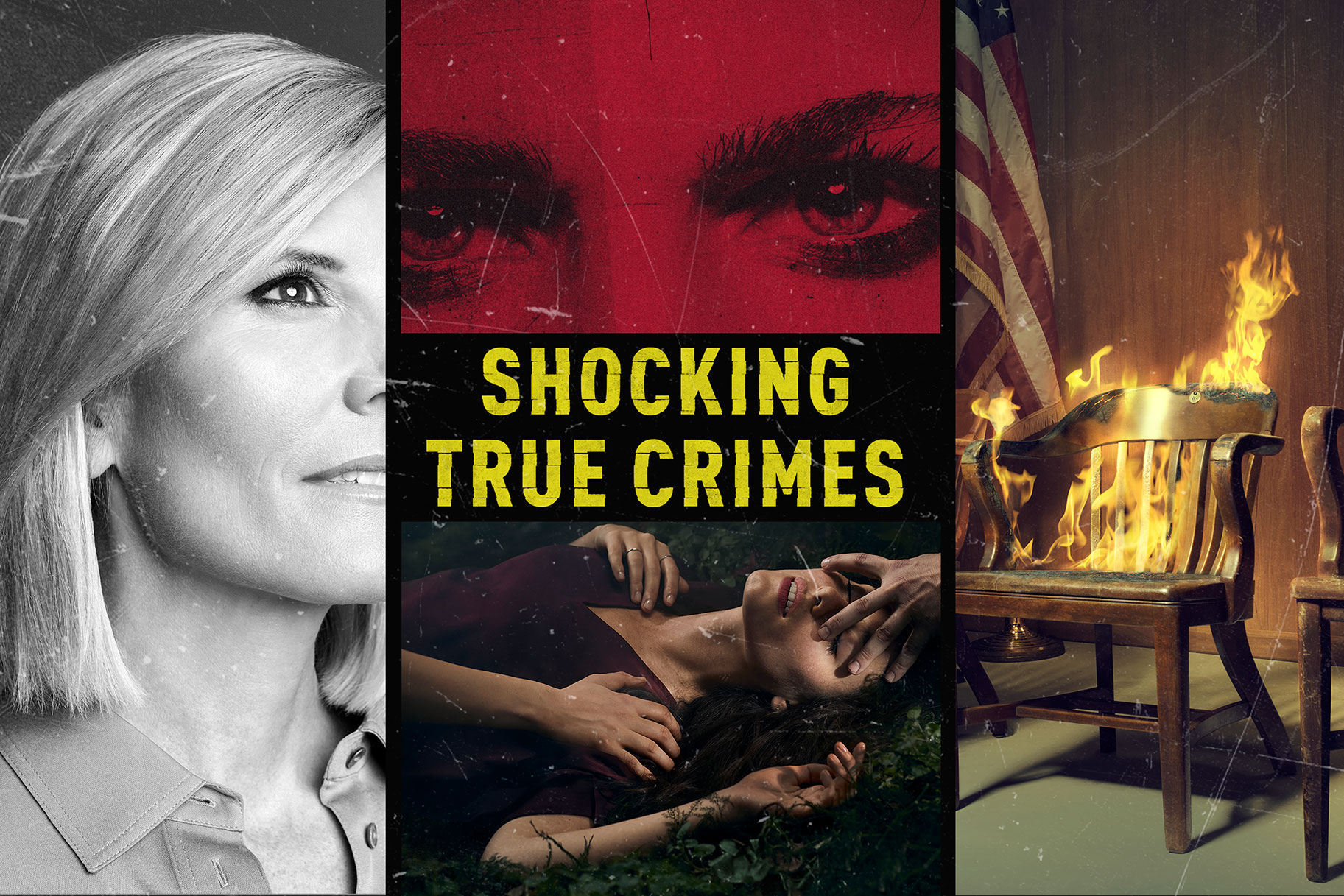

True Crime Shows To Stream On Oxygen's Free App

As i understand it, you can record several servo positions onto a micro sd using potentiometers, and then use a different bit of code in order to play the values back. We will read the data from potentiometer and from dht11 temperature sensor, and we will write this data to the sd card. The signals from these models are saved as data points in.

The project demonstrates how to initialize the sd.

This project is a simple data logger for microcontrollers (arduino, esp32, stm32), which records sensor data to a csv file on an sd card. You can use sd card logging to save signals from simulink ® models on an sd card mounted on a vex ® edr v5 robot brain. I want to use pc sdk to write a c# application that can monitor and raise notification when robot program is changed (not robot data, just code). Simply resets the tick count of the decoded encoder tick count variable held in the ur.

Hello there, i’m using conveyor tracking with encoder incremental i need to monitoring the value of encoder tick count to synchronize encoder for robot with encoder for. With the ur script function set_conveyor_tick_count (), you can simulate the conveyor motion.